Powering Success Through Advanced Technology

Co-Owner

Digvijay Engineers

Digvijay Engineers sees HIMTEX 2024 as an opportunity to reach its target customers and demonstrate how its power press machines can meet their specific needs and streamline manufacturing processes.

Jigneshbhai Bhuva, Co-Owner, Digvijay Engineers, is thrilled to be part of HIMTEX, which he points out is significantly beneficial for the business. “HIMTEX gathers industry professionals, including manufacturers, suppliers, and buyers, providing excellent opportunities for networking and fostering business relationships,” he states.

Participating in such events, he adds, enhances brand visibility and helps one reach the targeted audience within the machine tool and manufacturing sectors. “One also gets to explore current market trends, competitor activities, and technological advancements in the industry,” says Bhuva.

Reaching Out

As a manufacturer of power press machines, the company aims to meet attendees from the following major industry sectors at the show. The industries include: Automotive, Aerospace, Metalworking and Fabrication, Consumer Electronics, Home Appliances, Construction and Building Materials, Machinery and Equipment Manufacturing, and Medical Device Manufacturing.

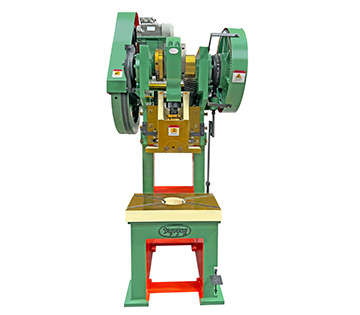

Power Press Machines

At HIMTEX 2024, Digvijay Engineers is showcasing its advanced Power Press Machine, engineered to deliver precision, efficiency, and safety in metal forming and cutting operations. “This state-of-the-art machine is a testament to our commitment to innovation and quality in industrial manufacturing solutions,” Bhuva remarks.

The machine’s key features include:

High Precision: The machine’s advanced control systems offer unparalleled accuracy and consistent and precise results for every press.

Robust Construction: Built with high-quality materials, the power press machine guarantees durability and long-term reliability, even in the most demanding industrial environments.

User-Friendly Interface: The intuitive control panel allows for easy operation and adjustment, minimizing downtime and maximizing productivity.

Safety Mechanisms: Equipped with the latest safety features, including emergency stop buttons, overload protection, and safety guards, ensuring a safe working environment.

Energy Efficiency: The machine is designed with energy-saving components to reduce power consumption and operational costs.

The machines are available in capacities ranging from 3–250 tonne, both mechanical and pneumatic, to suit different industrial requirements. The stroke length is adjustable to accommodate various material thicknesses and application needs. It operates at high speeds with adjustable settings for optimal performance. The table size features a spacious area to support a wide range of workpieces and tooling setups.

Catering to a Wide Range of Applications

The company’s power press machine is versatile and ideal for a variety of applications, including:

Automotive Industry: For forming, cutting, and assembling parts such as body panels, chassis, and other components.

Metal Fabrication: For shaping, cutting, and punching metal sheets and plates into desired shapes and sizes.

Aerospace Industry: For manufacturing various aircraft components that require precise and durable metal forming.

Consumer Electronics: For producing metal components for electronic devices such as casings and frames.

Construction Industry: For producing structural components like beams, channels, and other metal supports.

Appliance Manufacturing: For creating parts for household appliances, including washing machines, refrigerators, and ovens.

Furniture Manufacturing: For making metal parts for furniture, such as frames and supports.

Electrical Industry: For manufacturing metal components for electrical equipment and enclosures.

With 34 years of experience in the industry, Digvijay Engineers brings unparalleled expertise and innovation to its products. The company's dedicated customer support team is always ready to assist with installation, maintenance, and technical queries. It also offers tailored solutions to meet specific operational needs and enhance manufacturing processes.

Digvijay Engineers is present in Hall & Stall: 3E19 at HIMTEX 2024. For more information on the company and its offerings: www.digvijaypowerpress.com