Capitalizing on the Opportunities

Nikhil Agrawal

Managing Director

Nagel Special Machines Pvt Ltd

Nagel Special Machines’ participation in HIMTEX 2024 underscores its commitment to staying at the forefront of industry advancements and continuing to deliver high-quality, reliable products to its clients. The event allows the company to tap into Hyderabad’s dynamic ecosystem, helping it drive innovation, enhance its capabilities, and forge new partnerships.

Nagel Special Machines Pvt Ltd is proud to participate in HIMTEX 2024, which Nikhil Agrawal, Managing Director, Nagel Special Machines Pvt Ltd, believes is a premier exhibition that stands at the forefront of the Machine Tools and Manufacturing Technologies industry. “HIMTEX, known for its comprehensive focus on the Machine industry and the Auto sector, offers an unparalleled platform for industry leaders to showcase innovations, network with peers, and explore new business opportunities,” he adds.

Nagel Special Machines, incorporated in 1992 in technical collaboration with Nagel Maschinen Und Werkzeugfabrik GmbH, a leading manufacturer of CNC machines for the Automotive sector, is looking for marketing sectors. Industries including Automotive Aerospace, Defence, Hydraulic, and Mechanical Engineering are the users of Nagel honing and superfinishing technology.

“Our participation in HIMTEX 2024 underscores our commitment to staying at the forefront of industry advancements and continuing to deliver high-quality, reliable products to our clients in the machine industry and auto sector,” says Agrawal.

Hyderabad: A Hub of Opportunities

Hyderabad, the host city for HIMTEX 2024, is rapidly emerging as a major hub for Aerospace and Defence manufacturing. “The city’s growth trajectory in these sectors presents a wealth of opportunities for our company. By tapping into Hyderabad’s dynamic ecosystem, we aim to drive innovation, enhance our capabilities, and forge new partnerships that will propel our growth in these critical markets,” he shares.

At HIMTEX 2024, the company looks forward to engaging with industry peers, showcasing its latest innovations, and capitalizing on the opportunities that Hyderabad offers to fuel its future growth.

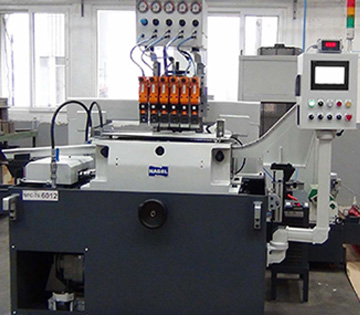

Centerless Through-Feed Superfinishing Machine

At HIMTEX 2024, the company highlights its Centerless Through-Feed Superfinishing Machine. Superfinishing is a short-stroke honing process to achieve the required surface finish on the outer diameter of the components.

The through feed machining operation is the most rational process. In through feed machines, the axes of the feed rollers are inclined 1/2 to 2.0 degrees in opposite directions, so that the components are fed and rotated simultaneously.

The surface finish is improved in stages by using several superfinishing stones of varying grades and harnesses. It is suitable for finishing all types of piston pins, gudgeon pins, piston rods, cylindrical rollers, bearing rollers, taper rollers, etc.

The Centerless Through-Feed Superfinishing Machine from the company is equipped with six stone guides and a PLC-controlled system. The machine cap has diameters ranging from 10 to 40 mm for pins or rollers. This machine is suitable for finishing various types of cylindrical components, including cylindrical pins, gudgeon pins, and cylindrical rollers.

The advantages of the machine include a reduction in noise due to the use of anti-friction and sliding bearings. Additionally, the high percentage of contact area results in increased load capability and reduced wear.

An example of an application is the piston pin, which is made from low alloy steel with a hardness of 58 to 62 HRC. The pin size is 36.00 mm in diameter and 62.50 mm in length. The input roughness is Ra 0.15, while the output surface achieves a roughness of less than 0.05 Ra. The feed rate for this process is 1.2 meters per minute.

Nagel Special Machines Pvt Ltd is present in Hall & Stall: 3/3C-10 at HIMTEX 2024. For more information on the company and its offerings: www.nagelindia.in